三州(三河)屋瓦的歷史可以追溯到江戶時代,是日本廣為人知的三大屋瓦產區(三州、石州、淡路)之一。

屋瓦產業隨著大城市的發展而繁榮。

其中,三州又因為能採集到大量適合製造屋瓦的優質黏土,並且有適合搬運重物的便捷海運環境,發展得特別迅速。

即使到了現代,承襲了屋瓦的製作技術和設計風格的三州瓦,仍是受到高度評價的高品質屋頂材料。

The history of Sansyu (Mikawa region) kawara dates back to the Edo period, and Sansyu is widely known as one of Japan’s three major kawara production areas (Sansyu, Sekisyu, and Awaji).

The kawara industry came to prosper with the development of big cities.

Sansyu was one region that saw tremendous development due to the large amounts of high-quality clay from the area suitable for kawara and its convenient marine transport, which was suitable for shipping heavy objects. Even now, Sansyu kawara are lauded as a high-quality roofing material that maintain those traditional techniques and designs.

-

首先將原料的黏土,用輸送帶送進黏土捏合機。

黏土是由大約15~20種的田間土、山土等土壤混合而成。 The clay that comprises the raw material is carried on a conveyor belt and enters the clay wedger.

The clay is made by mixing around 15 to 20 types of soil from rice paddies, fields, mountains, and other locations. -

將空氣從經過機器捏合的黏土中充分去除後,擠壓成片狀。去除空氣,是為了防止黏土在烘烤時裂開。 After a sufficient amount of air is removed from the clay in the wedger, it is extruded in the form of strips.

The air is removed to prevent cracking when the clay is fired. -

將擠出的黏土片切成相當於一塊屋瓦的長度,並一塊塊分別放入瓦片形狀的模具中塑形。每分鐘可製作出28塊瓦片。 The extruded strips of clay are cut to the length of one kawara, then each piece is placed in a kawara-shaped mold to create the kawara’s shape.

The line produces 28 tiles per minute. -

接著用吸盤將完成塑形的瓦片放到棧板上,送進乾燥室。

在乾燥室當中,會用130℃到150℃的熱風,花上1~2天時間烘乾瓦片。 The shaped kawara are placed on pallet with suckers and put into the drying room.

Air flows in the drying room at temperatures of 130°C to 150°C, and the kawara are dried for one to two days. -

從乾燥室出來的瓦片(未上色),會由懸掛式輸送機搬運,並在表面塗上釉藥。

釉藥是由黏土、玻璃和金屬摻水混合而成。 The kawara (with white background) removed from the drying furnace are carried by a hanger conveyor, and glaze is applied only to the front surface.

The glaze is a mixture of clay, glass, and metals in water. -

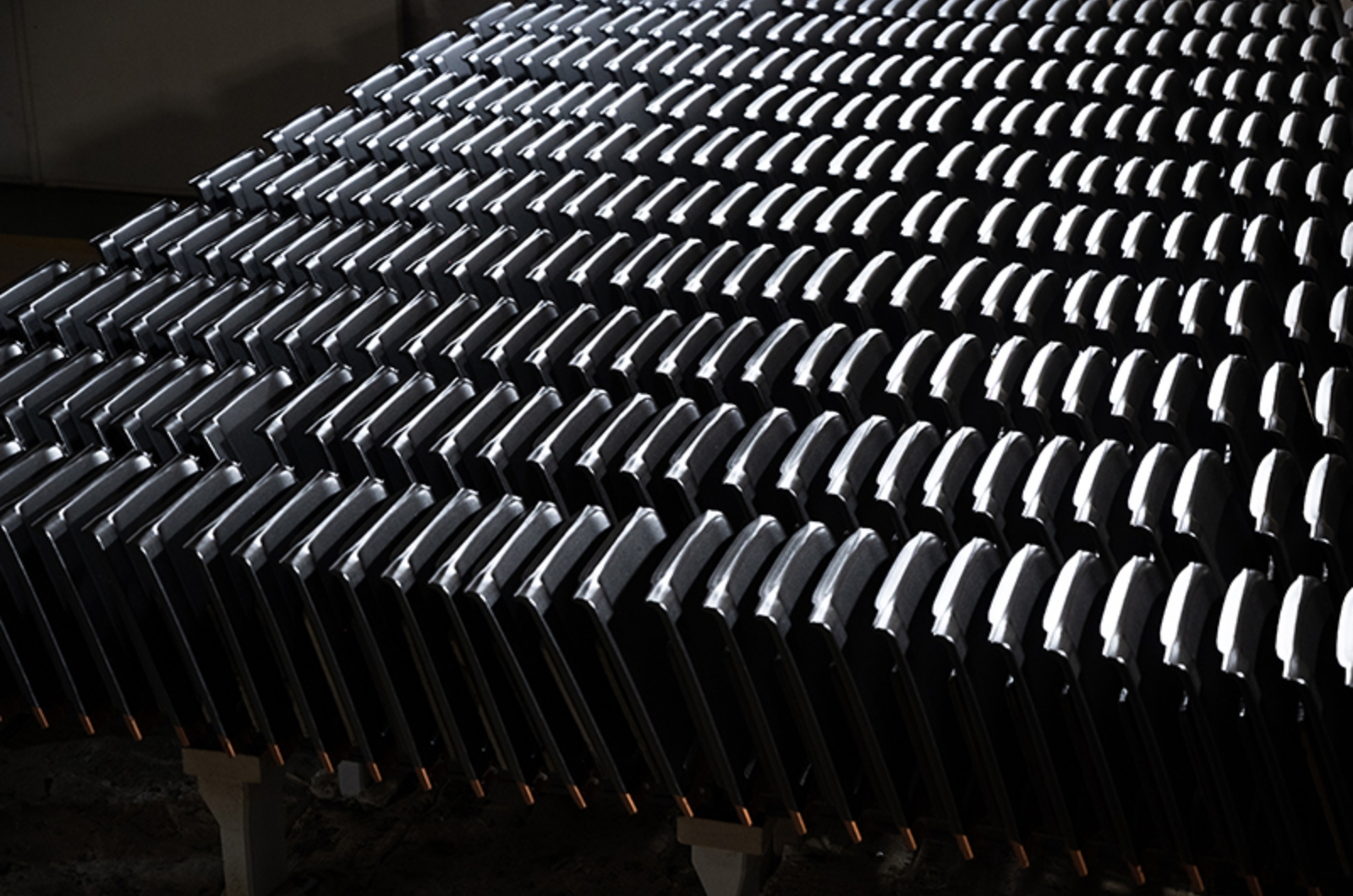

為了烘烤,需要將瓦片豎立在推車上。

逐漸提高窯溫至1135℃~1145℃,並烘烤10~14個小時。 For the firing process, the tiles are stood up and loaded onto a cart.

The temperature in the kiln is gradually increased to 1135-1145°C, and the pieces are fired for 10-14 hours. -

檢查所有燒製完成的瓦片釉色,以及是否有表面刮痕。

用錘子敲打瓦片,透過聲音辨別瓦片有無裂痕。

瓦片的彎曲度則使用自動檢測裝置一一測量,彎曲度過大就會自動被挑開。

此外,每天還會取幾塊瓦片,檢查尺寸、彎曲度、強度、每24小時的吸水率,只有符合規格的瓦片,才能正式出貨。 All of the fired kawara are inspected for surface scratches and glaze color.

Inspectors hit the kawara with a hammer and listen to the sound to check for cracks and splitting.

The twisting of the kawara is measured one by one with an automatic inspection device. If the degree of twisting is too great, the kawara is automatically ejected.

In addition, several kawara are taken out each day and inspected for dimensions, bending, strength, and 24-hour water absorption. Only those kawara passing the standards are shipped. -